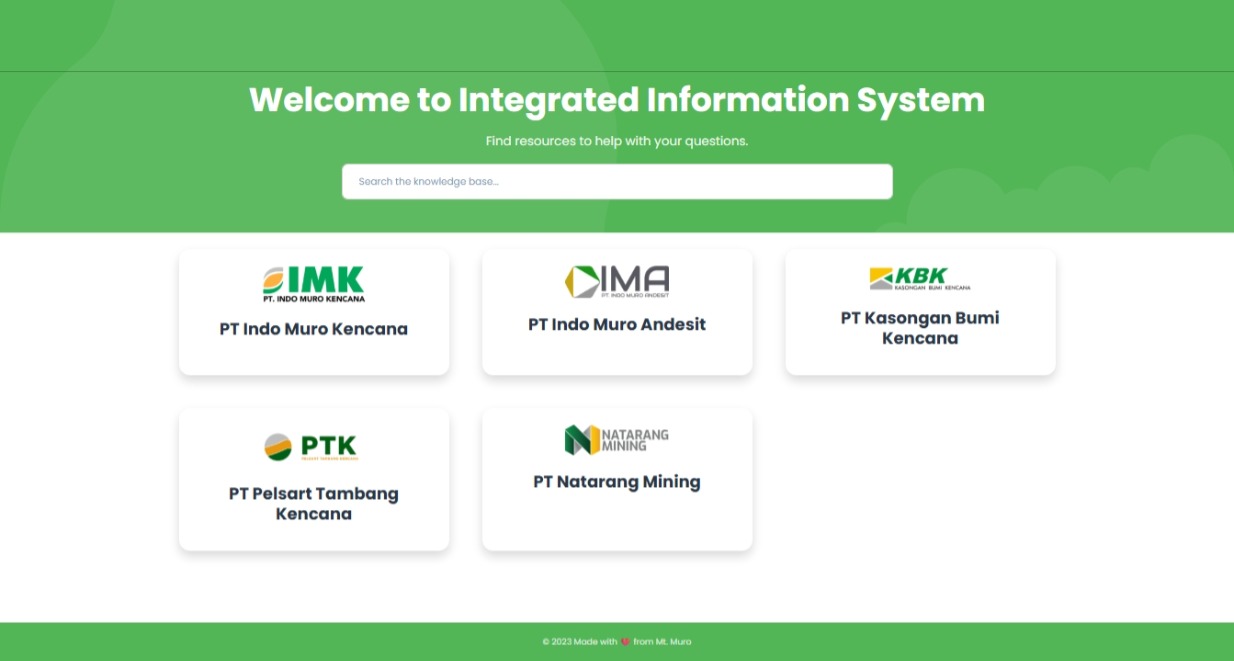

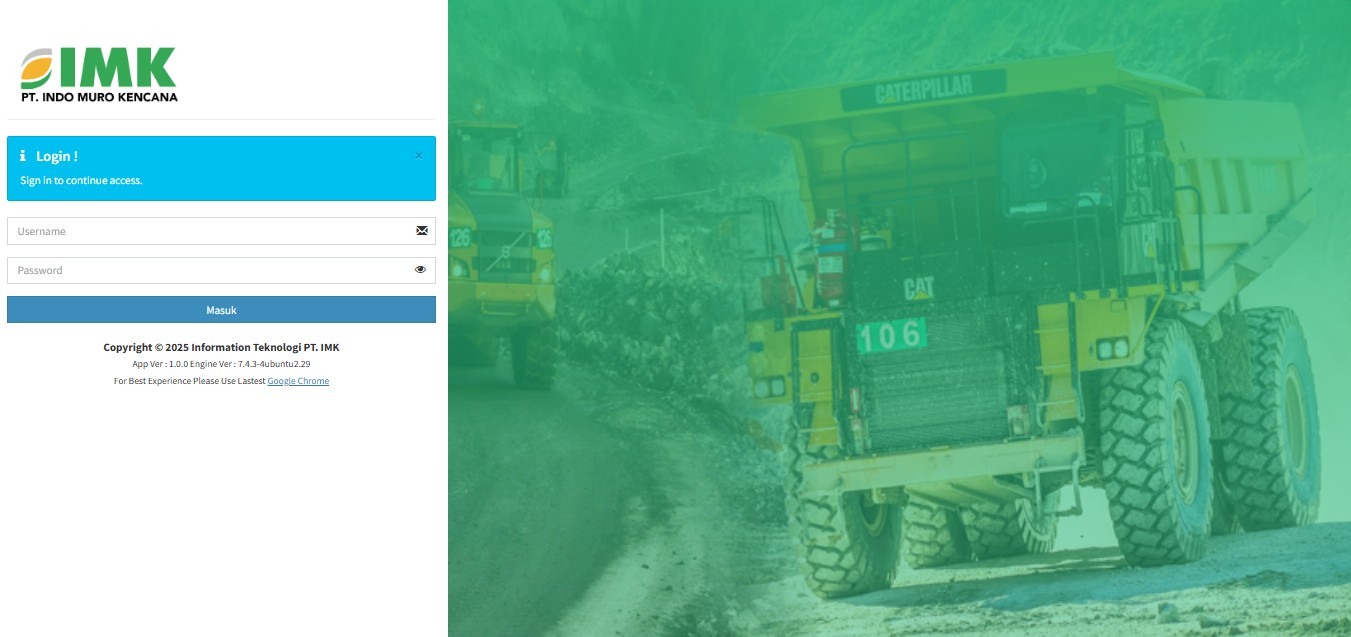

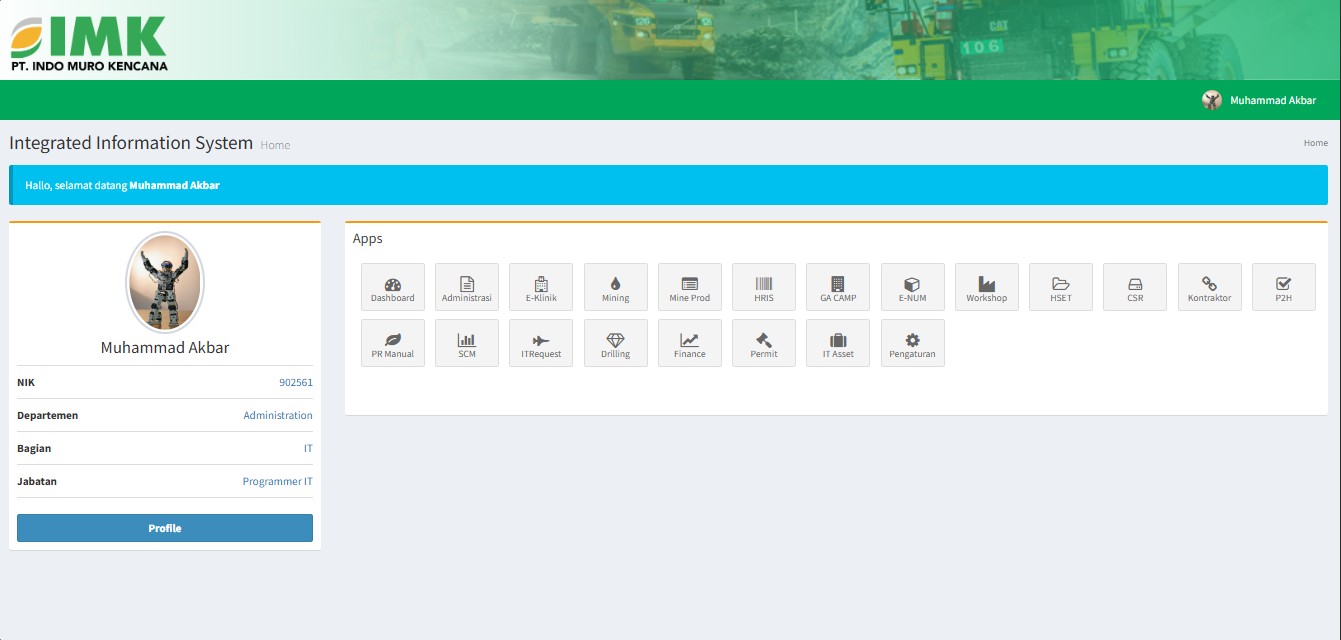

Integrated Information System (IIS)

Administration

Manage employee/department administration needs like Timesheet, Forms, Balance, Unit Lending/Borrowing and many more

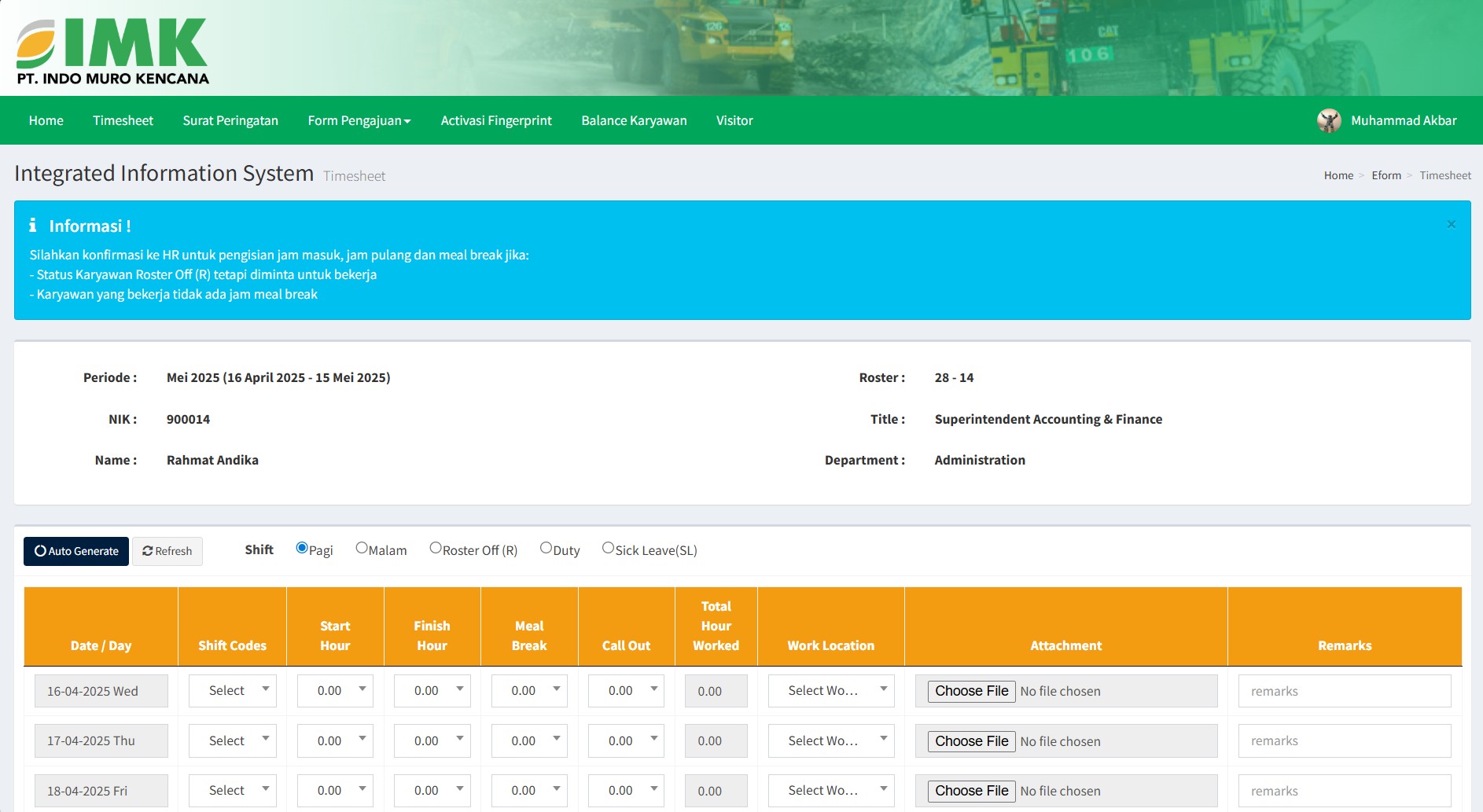

The Employee Timesheet feature in the IIS (Integrated Information Systems) web application is designed to accurately track and record employees' daily working hours. This module allows the Admin Department to input and manage timesheet data, ensuring that attendance, working hours, and overtime are properly documented for each employee.

Dashboard

Serves as a centralized monitoring tool for Heads of Departments to oversee key operational metrics in real-time.

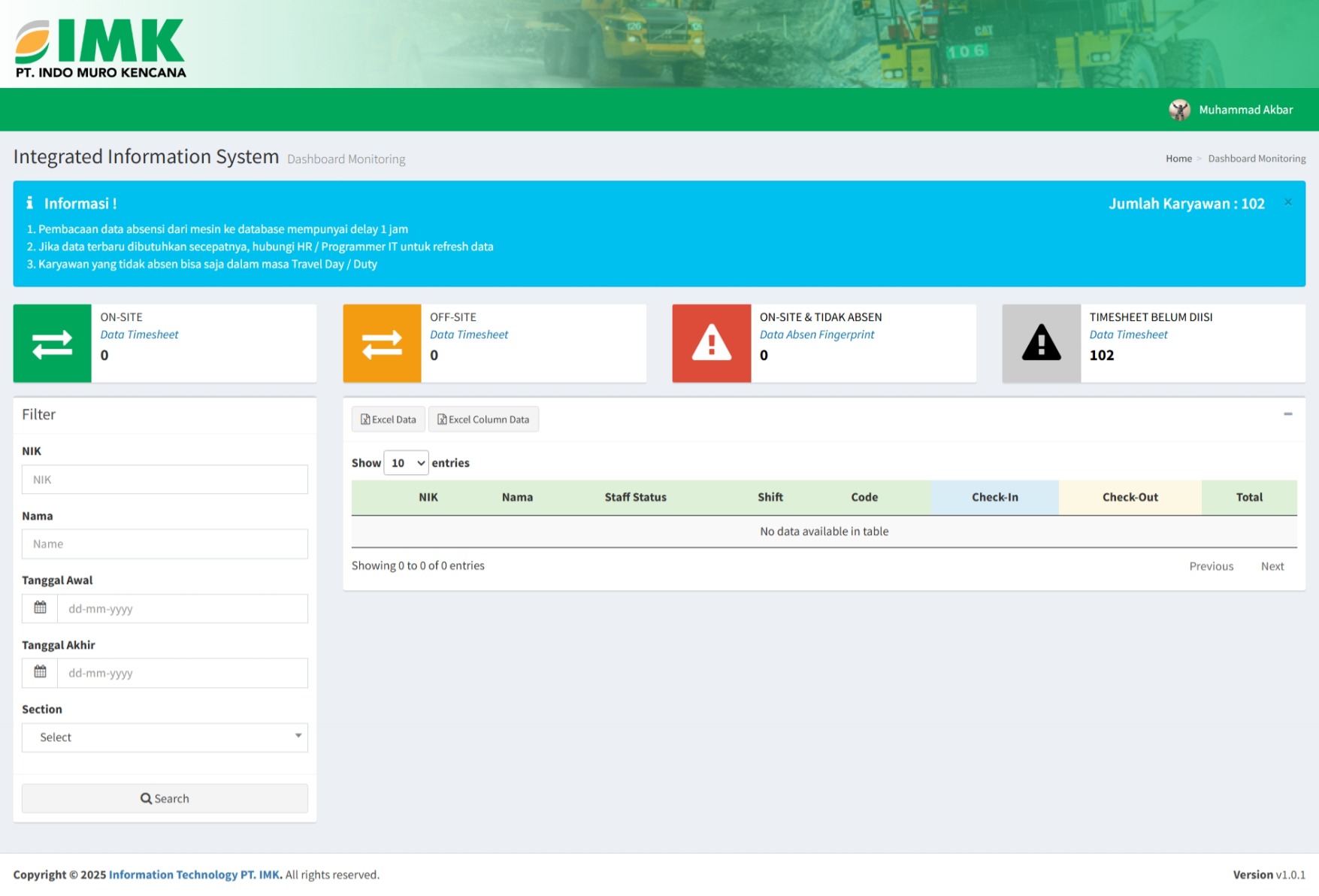

The Attendance feature provides Heads of Departments with a clear and up-to-date overview of employee attendance patterns. This feature displays key metrics such as daily presence, absences, late arrivals, and attendance trends over time, allowing managers to quickly identify irregularities or potential issues within their teams.

E-Klinik

Manage clinic administration and patient record

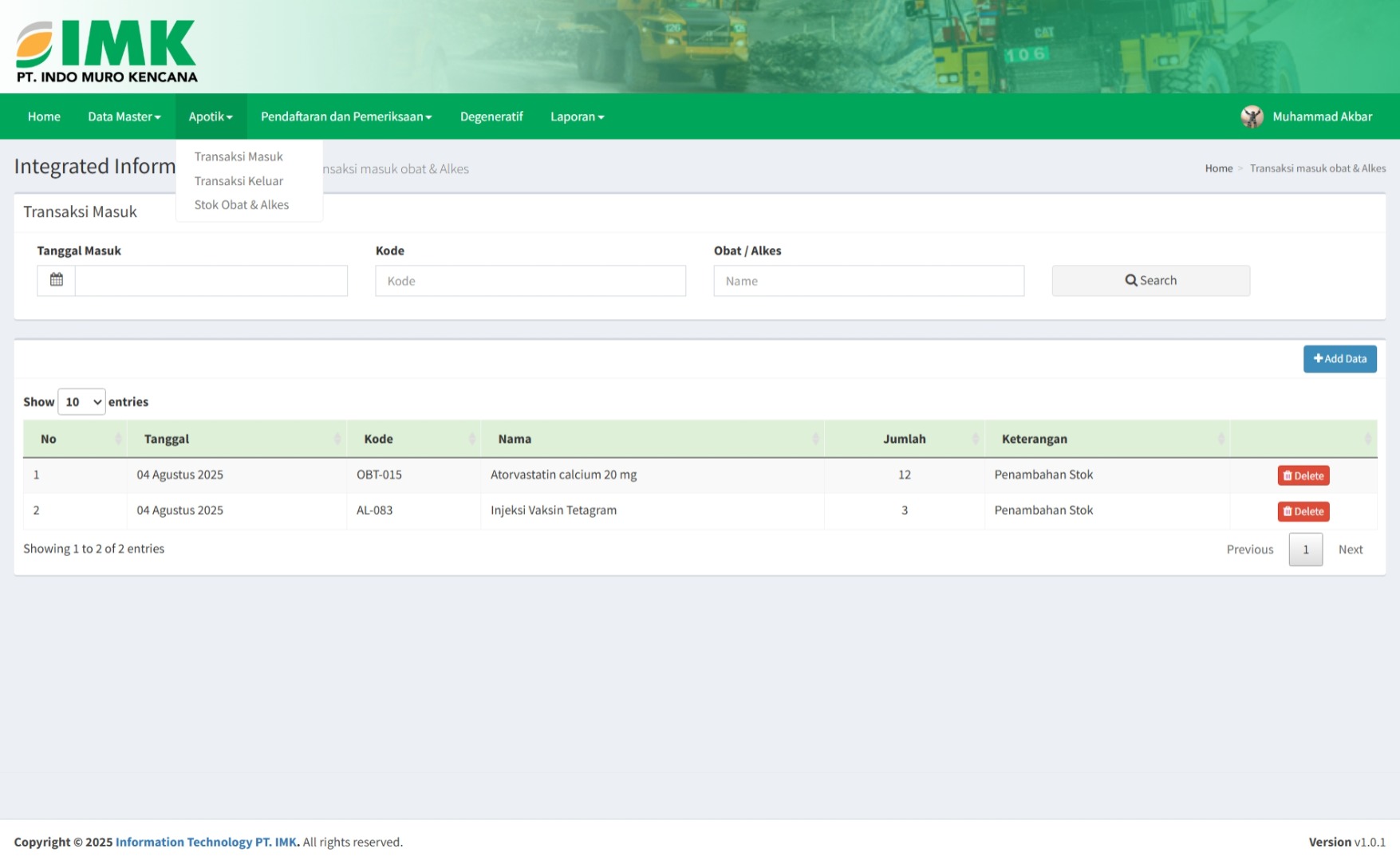

The Medicine Transaction In & Out feature in the E-Clinic module of IIS (Integrated Information Systems) is designed to manage the inventory flow of medical supplies within the clinic. This feature records every incoming and outgoing medicine transaction, providing accurate stock tracking and preventing shortages or overstocking. The system ensures transparency, supports stock audits, and helps clinic staff maintain optimal inventory levels to meet daily healthcare needs efficiently and responsibly.

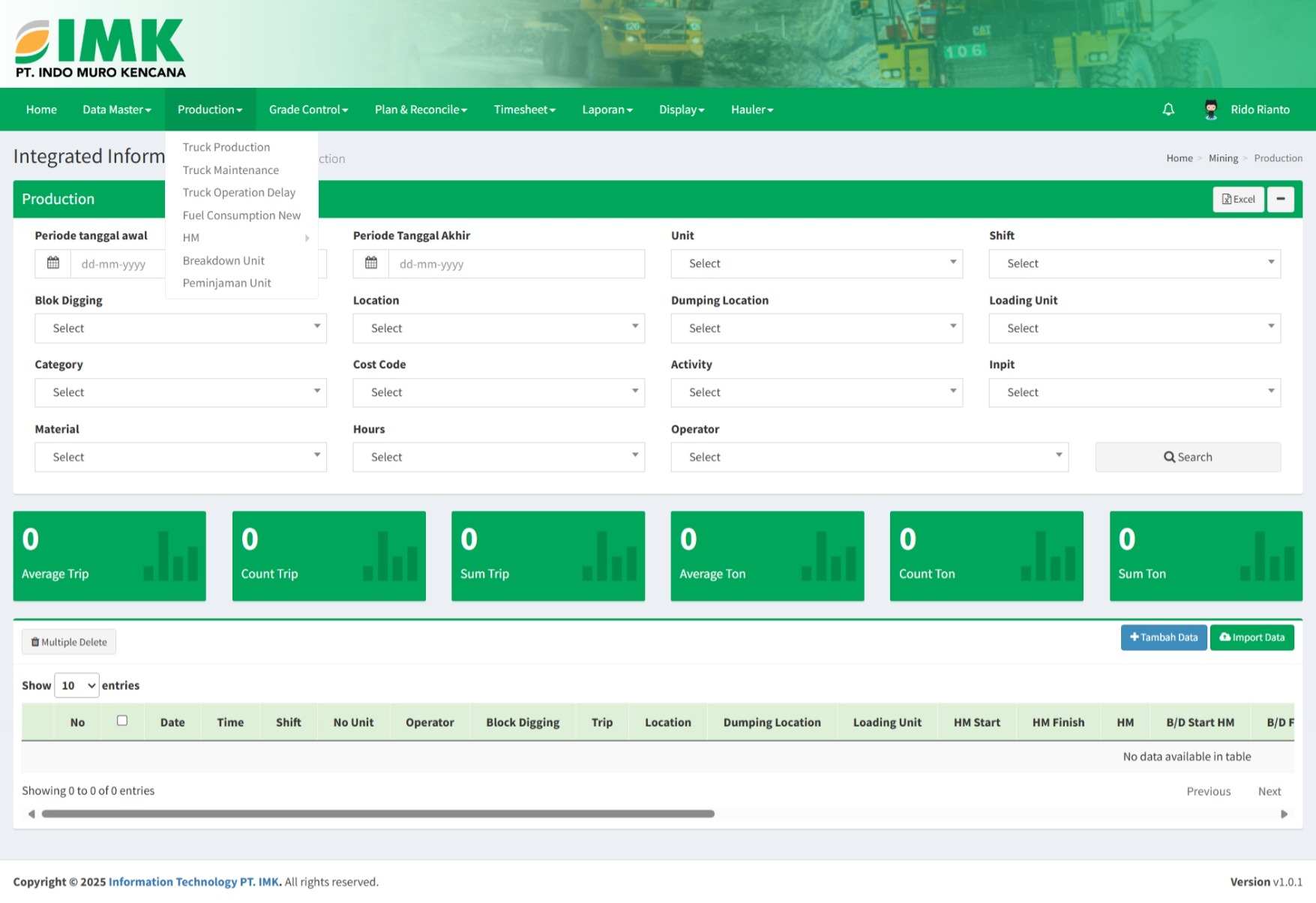

Mining Operation

Day-to-day extraction activities record

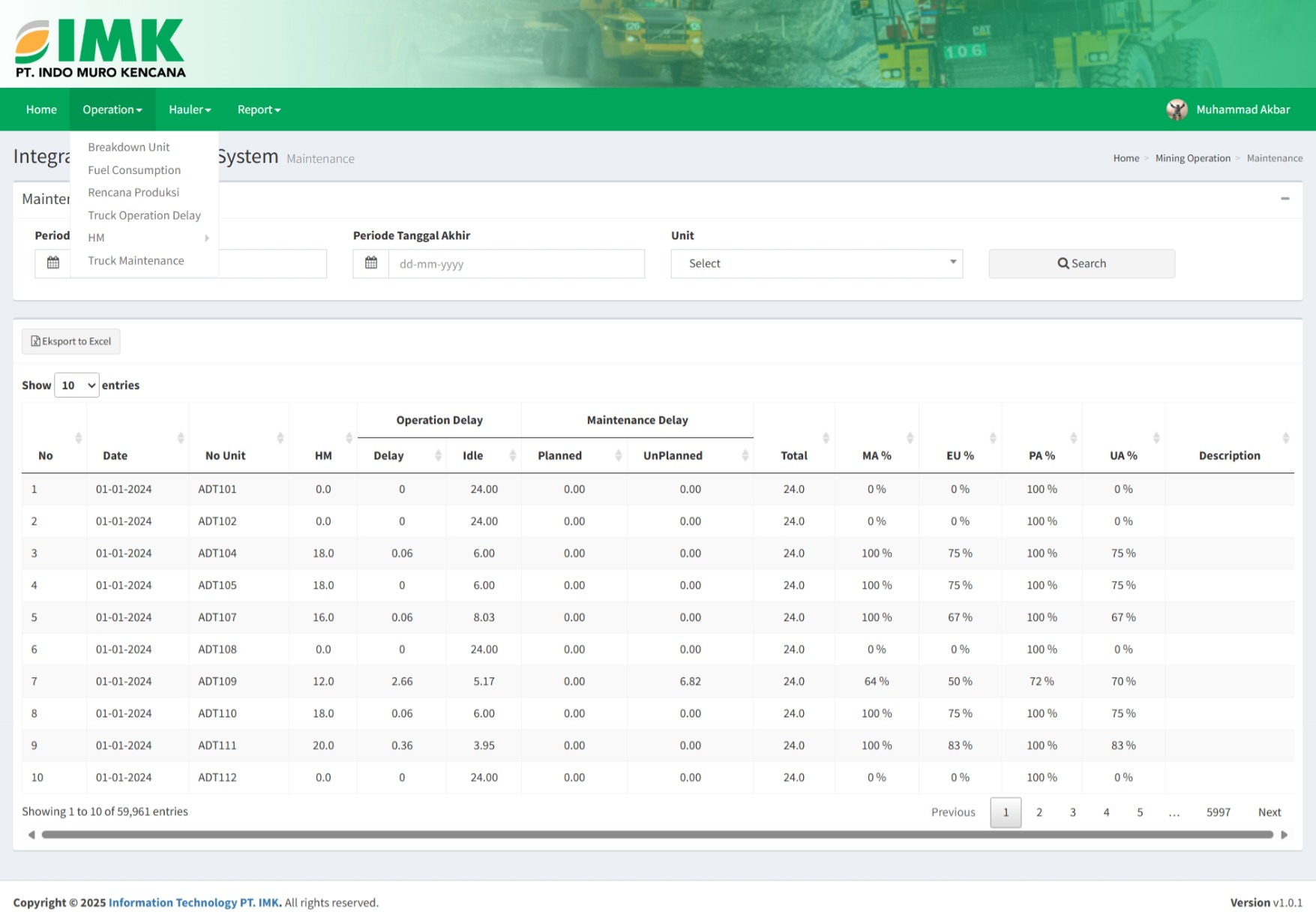

The Truck Maintenance feature in the Mining Operation module of IIS (Integrated Information Systems) displays detailed information on each haul truck’s operating hours, delays, and maintenance records, including operation delays, idle time, planned and unplanned maintenance, as well as performance indicators such as Mechanical Availability (MA%), Equipment Utilization (EU%), Physical Availability (PA%), and Utilization Availability (UA%). This feature helps monitor equipment performance, schedule maintenance efficiently, and ensure high equipment availability. In addition to Truck Maintenance, the Operation menu also includes several other sub-features such as Breakdown Unit for tracking equipment failures, Fuel Consumption for monitoring fuel usage per unit, Rencana Produksi for planning and evaluating production targets, Truck Operation Delay for identifying lost time due to operational issues, and HM (Hour Meter) for recording unit operating hours to support maintenance scheduling and operational planning.

Mining

Strategic and technical aspects of the entire mining lifecycle

Provides comprehensive data input and filtering capabilities for monitoring hauling activities, with fields for selecting date range, unit, shift, operator, location, block digging, dumping and loading units, material type, and other operational parameters. It displays key performance metrics such as Average Trip, Count Trip, Sum Trip, Average Ton, Count Ton, and Sum Ton, enabling detailed tracking and analysis of hauling efficiency. In addition, users can import or manually add data entries and view details like trip time, location, and HM (hour meter) records. The topbar within the Production module also includes several related sub-features such as Truck Production, Truck Maintenance, Truck Operation Delay, Fuel Consumption New, HM (Hour Meter), Breakdown Unit, and Peminjaman Unit (Unit Lending)—each offering specific insights and tools for managing production operations, equipment performance, and resource allocation across the mining site.

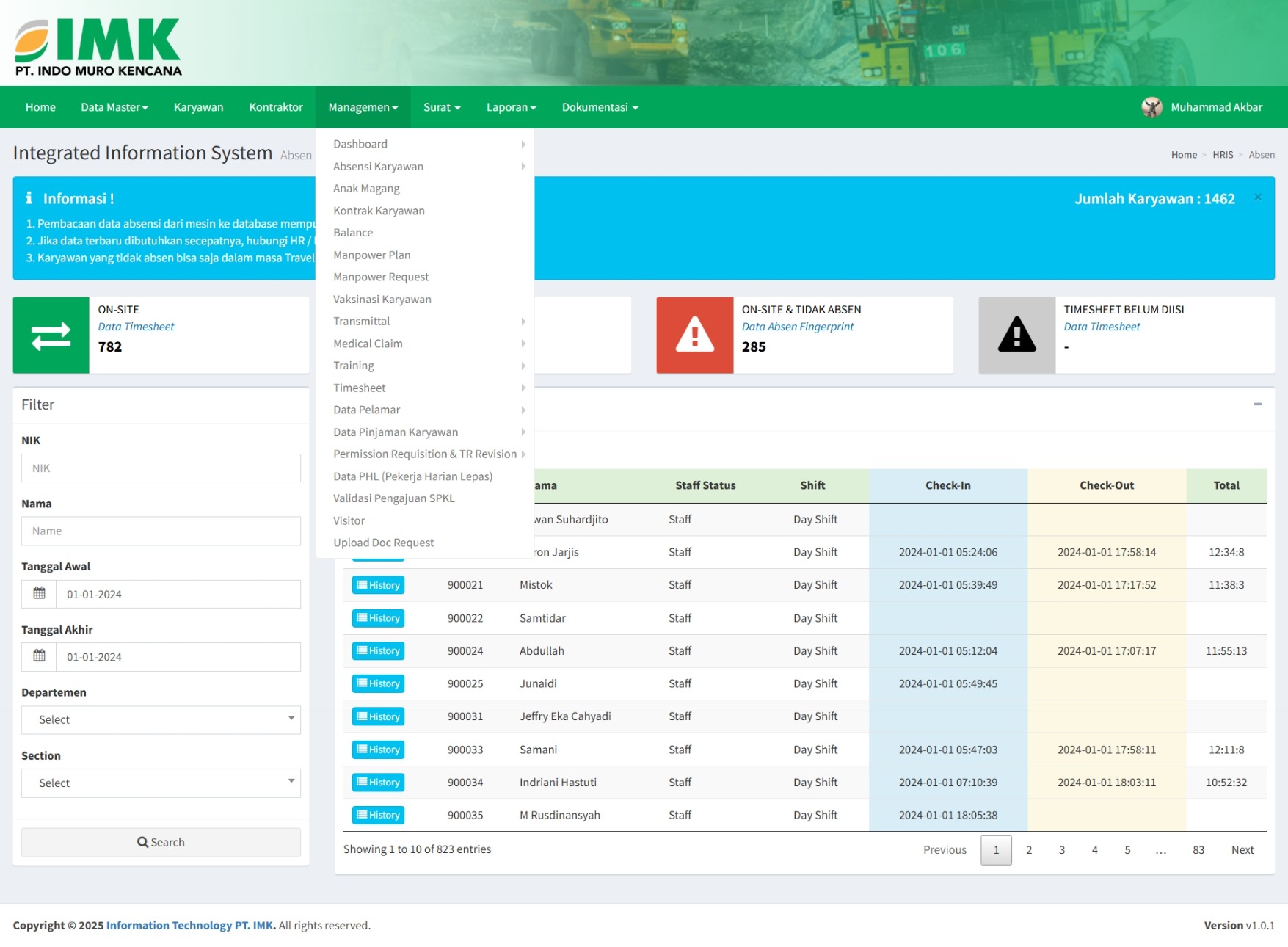

HRIS

Helps organizations manage and automate HR tasks like employee data, payroll, recruitment, attendance, performance, and benefits—all in one centralized system. It streamlines processes, reduces paperwork, and improves accuracy in HR operations.

The Management menu in the HRIS module centralizes various HR operational features, starting with Absensi Karyawan for tracking employee check-in, check-out, and total work hours, complemented by Anak Magang to manage intern data, Kontrak Karyawan for monitoring employment contracts, Balance for leave or quota tracking, Manpower Plan and Manpower Request for workforce planning and staffing needs, Vaksinasi Karyawan to record employee vaccinations, Transmittal for document submissions, Medical Claim for processing reimbursements, Training to log employee training activities, Timesheet for recording work allocations, Data Pelamar for applicant records, Data Pinjaman Karyawan for loan management, Permission Requisition & TR Revision to handle leave or travel changes, Data PHL for casual labor records, Validasi Pengajuan SPKL for overtime approval, Visitor for guest entry logs, and Upload Doc Request for submitting required HR documents.

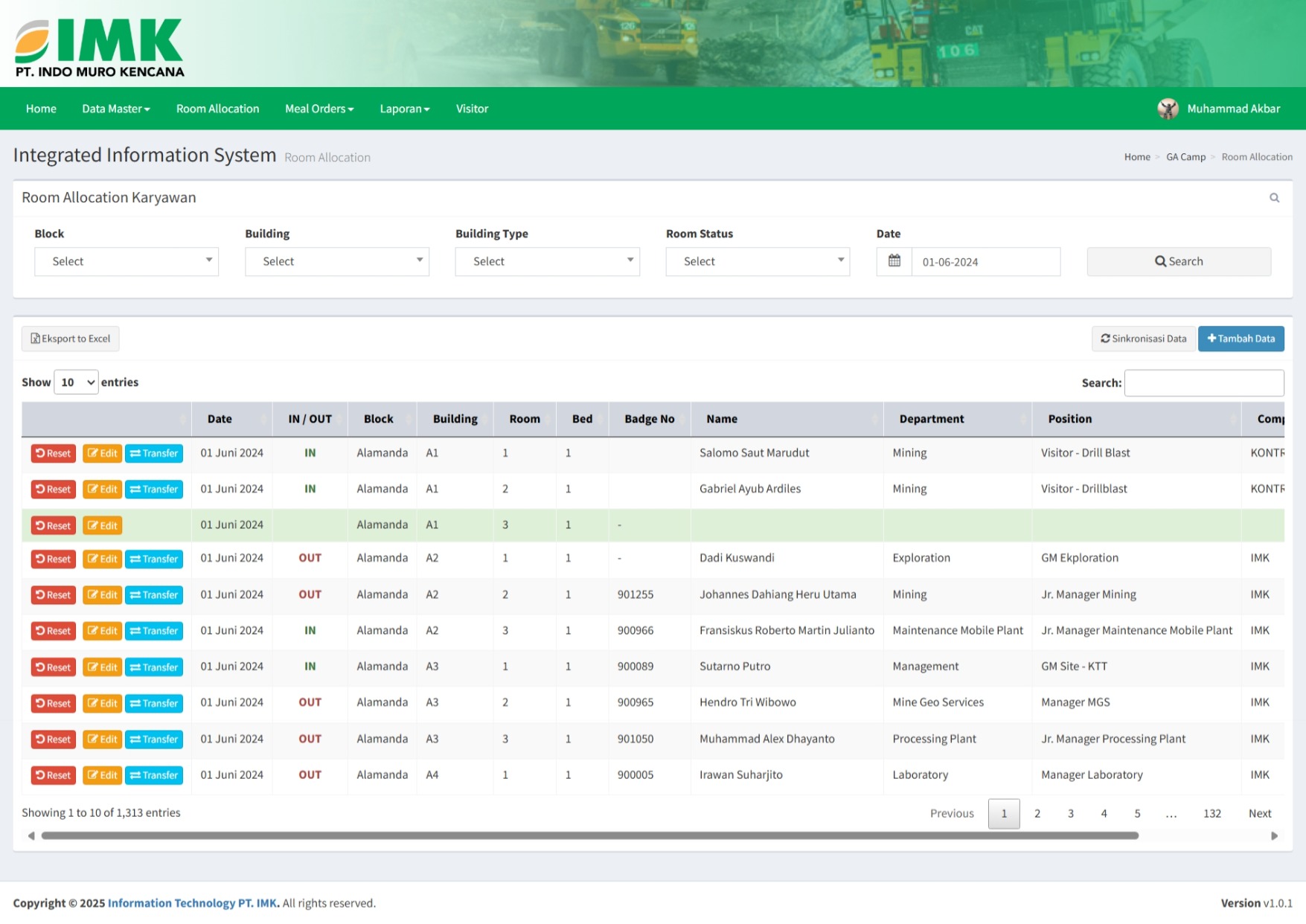

General Affair

Manage non-core operational services that support daily business activities and employee needs.

In the GA module, one key feature is room allocation management, which handles the assignment of dormitory rooms for employees, contractors, and visitors. This feature keeps track of available rooms, occupancy status, and stay duration, ensuring that accommodations are efficiently distributed and updated in real time. It can manage check-in/check-out processes, record occupant details, and monitor room conditions for maintenance needs. By automating these tasks, the system helps avoid double-booking, optimizes space utilization, and provides clear records for auditing and reporting purposes. This ensures a smooth lodging arrangement process and enhances overall hospitality for all occupants.

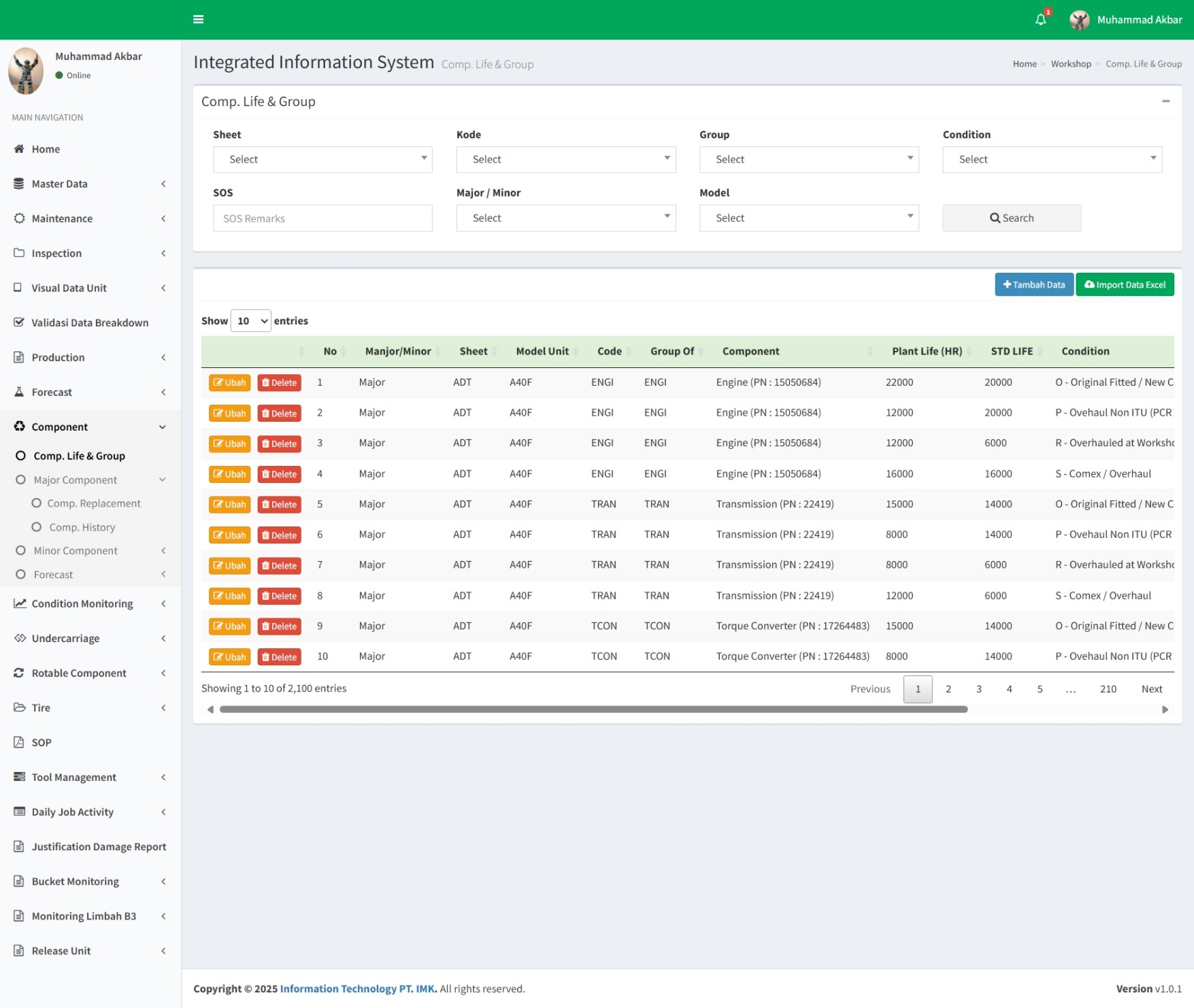

Maintenance Mobile Plant

Manage and track maintenance activities for all mobile equipment and heavy machinery used in operations.

Manages and monitors the lifecycle of major and minor components in mobile plant equipment, such as engines, transmissions, and torque converters, by tracking plant life hours, standard life expectancy, and current condition to ensure optimal performance and timely replacements; it features powerful filtering and search tools, a detailed component data table, and options to add, edit, delete, or bulk import data from Excel, while also providing submodules for major and minor component management, component replacement records, historical usage logs, and forecasting tools to predict future replacement needs based on usage trends.

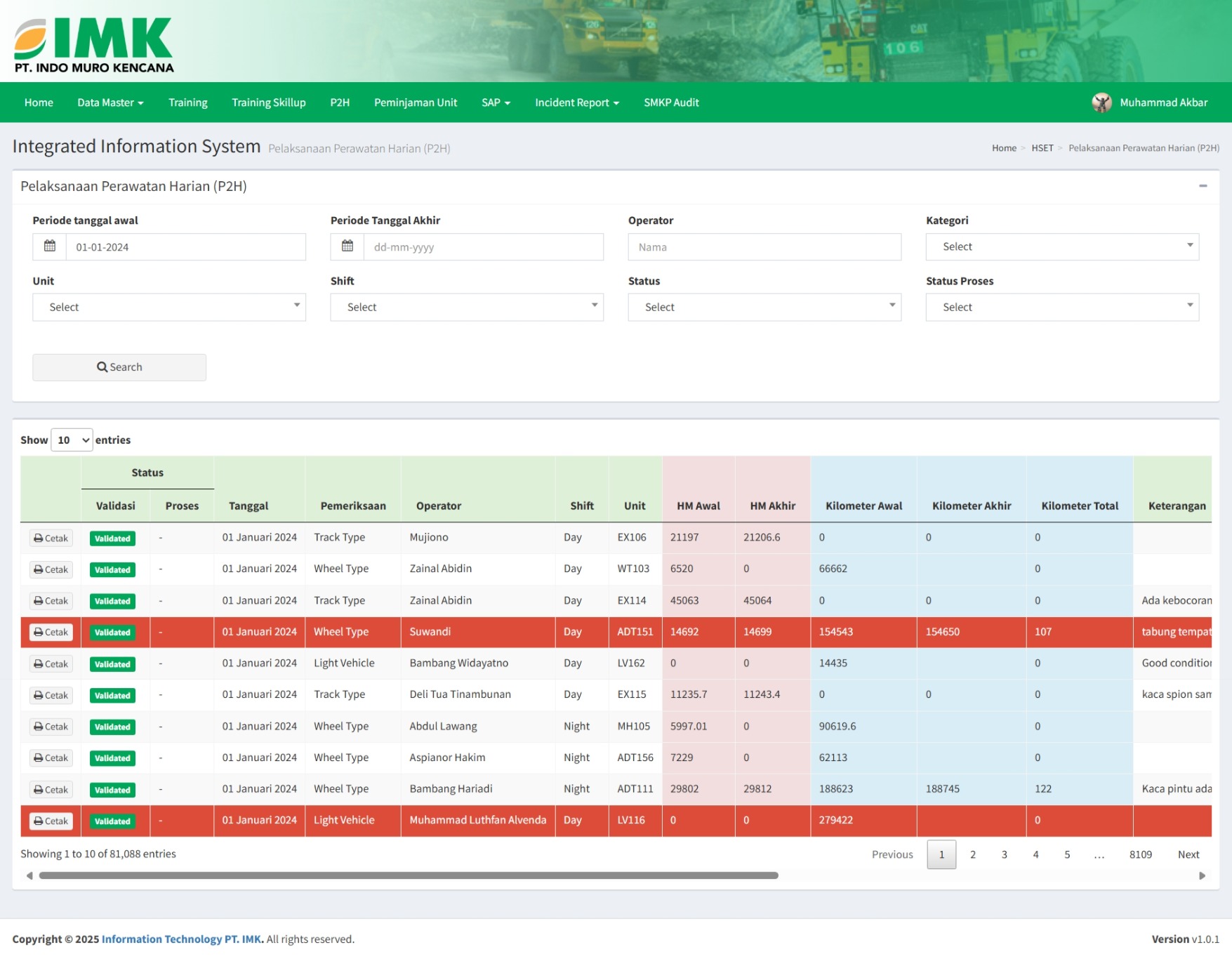

HSET

Manage workplace safety, environmental compliance, health monitoring, and employee training activities in a centralized platform

Daily inspection checklist that operators must complete before using equipment, covering details such as unit type (track, wheel, or light vehicle), identity, shift, HM/KM readings, and inspection results across all key components, with space for notes and signatures; it ensures every unit is inspected systematically, enhances accountability through supervisor validation, minimizes the risk of undetected issues, and provides accurate, real-time records to support safety and operational reliability.

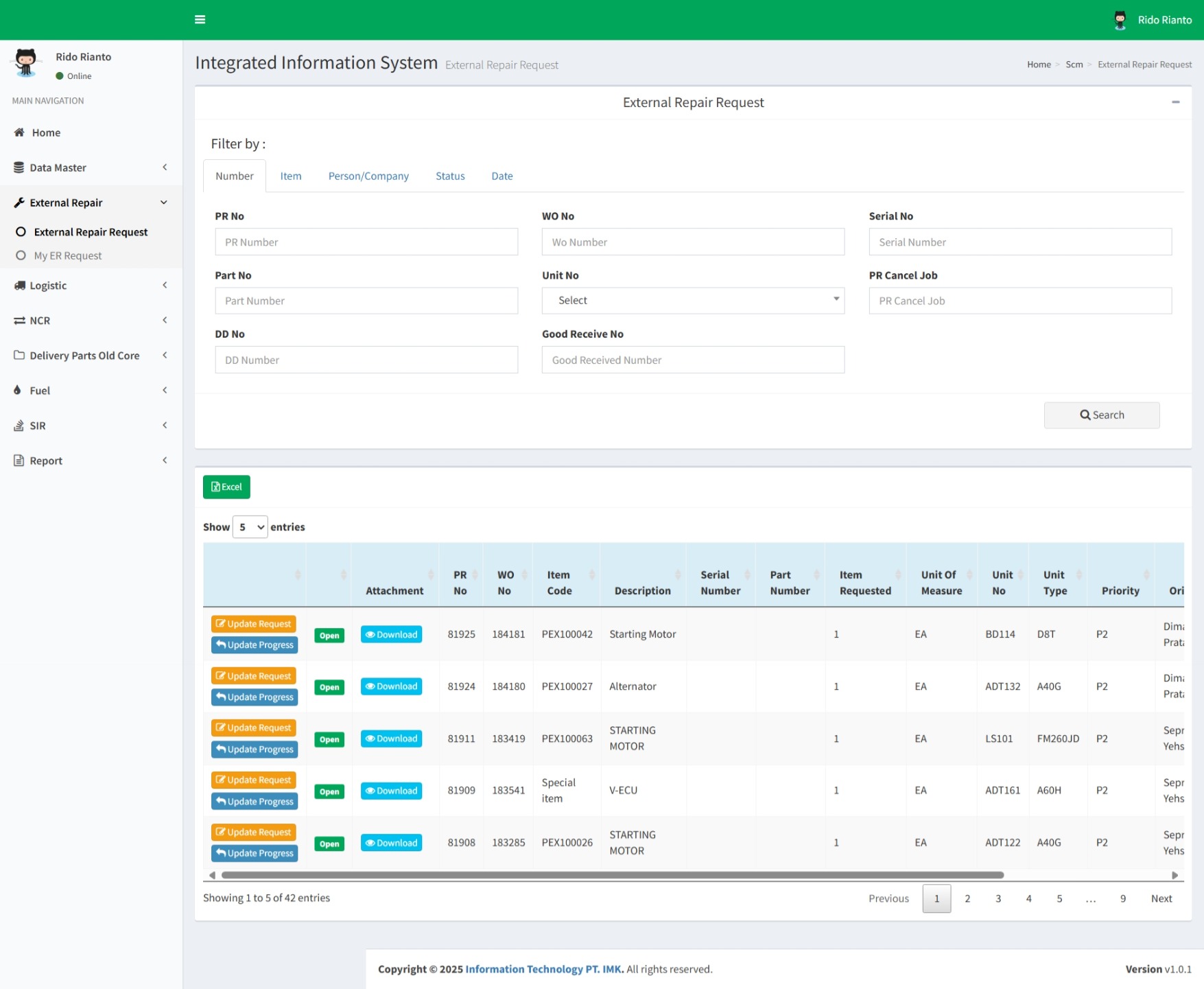

Supply Chain Management

Streamline and integrate the flow of goods, services, and information across procurement, inventory, logistics, and distribution processes within the company.

Manage repair requests for parts or equipment that cannot be fixed internally and need to be sent to an external vendor or workshop. It allows users to create, track, and update repair requests by filling in detailed information such as PR (Purchase Request) number, WO (Work Order) number, serial number, part number, and unit details. The system also provides visibility on the progress of each repair through status updates, attachments, and reports, ensuring full traceability from request submission until the repaired item is received back. This feature helps streamline communication with external vendors, monitor turnaround times, and maintain accurate records of repair activities to support operational continuity.